| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | DZK |

| Model Number : | OD |

| Certification : | ROHS |

| Price : | USD 2.0/PCS |

| Payment Terms : | L/C, T/T |

| Supply Ability : | 1000000PCS/MONTH |

| Delivery Time : | 7-10 days |

OD 1100 052 00171,HBTS 110 125.1 6.3,Hydraulic Oil Cylinder ROD SEAL,PTFE+NBR Combined Sealing,PARKER OD TYPE SEAL

1. Product Description:

2. Product Characteristic:

● Low friction resistance: no crawling phenomenon, good performance when lubrication and no lubrication, can ensure that the equipment is running smoothly.

● Good sealing effects: Movement and static sealing effects are quite good, without stickiness, which can effectively prevent leakage. Under low rubbing resistance, the leakage can also be controlled to excellent conditions.

● High pressure resistance: strong working conditions and high pressure can be afforded, such as widely used in some high -pressure hydraulic systems.

● The groove structure is simple: easy to install and maintain, save installation space.

● Long service life: good abrasion loss performance, coupled with good material characteristics to make it have a longer service life.

Operating pressure | ≤ 60Mpa |

Operating temperature | -35 °C to +200 °C |

Sliding speed | ≤4M/S |

| Media | Hydraulic oil |

4. Commonly Used Material:

| Material: | Temperature: |

| NBR | -40 to 100 ℃ |

| FKM | -20 to 200 ℃ |

| FFKM | -20 to 320 ℃ |

| HNBR | -40 to 150 ℃ |

| AFLAS | -30 to 175 ℃ |

| VMQ/SILICON | -70 to 220 ℃ |

| FVMQ | -60 to 175 ℃ |

| EPDM | -50 to 150 ℃ |

| CR | -40 to 120 ℃ |

| SBR | -40 to 110 ℃ |

| PU | -40 to 90 ℃ |

| PTFE | -100 to 280 ℃ |

| IIR | -20 to 120 ℃ |

| ACR | -25 to 150 ℃ |

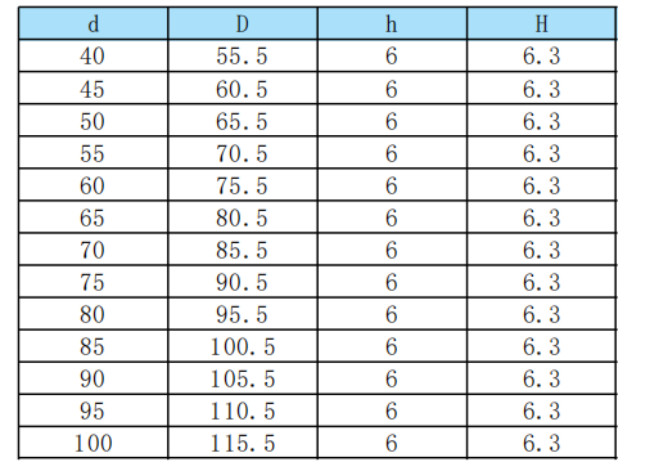

5. Product specification:

6. Installation:

The installation method of OD type seal as follows:

1. Preparation before installation: Wash and oil all the sealing substrates, sealing and installation tools of OD type seal.

2. Install the rubber ring: put the rubber ring of Steter into the groove, not to be distorted.

3. Install the PTFE sealing ring: compressing the PTFE ring of Steter into the shape of the waist, and not to form a pointed bending, and then put the compressed PTFE sealing ring into the groove, and gently flatten it by hand.

4. Install the restoration of the heart shaft: push the restoration's heart shaft to the sealing part, and gently turn the heart shaft. Place it for 1 minute to remove the axis and install it.

|